Paolo Tiramani, CEO and Founder of Boxabl, a technology startup focused on modular construction, discusses the benefits and challenges of his company’s work to revolutionize the residential building industry. Boxabl offers stackable, modular buildings that can be shipped on a trailer, assembled on site in under an hour, and customized to meet the needs of end users. These buildings offer cost-saving benefits for developers, such as the ability to ship on their own trailer systems and eliminating the need for cranes or overnight stops. Boxabl also provides plans for necessary site work and ports all hookups to one side for easy access. Tiramani also talks about the company’s successful crowdfunding efforts and partnerships with the Department of Defense and D.R. Horton.

—

Watch the episode here

Listen to the podcast here

Not Your Father’s Modular…How Boxabl Seeks To Change Construction With Paolo Tiramani

My guest is Paolo Tiramani. He is the CEO and Founder of Boxabl, a technology startup that’s on a mission to significantly lower the cost of homeownership for everyone. Boxabl creates and produces stackable, highly modular, and portable building solutions, which can be unpacked on site in under an hour. Elon Musk has one of them.

We have Paolo on the show because we want to talk about modular construction, the limitations of modular, and also the possibilities of how you can bring modular construction to the residential industry specifically, and still maintain customization and architectural beauty. We also talk about the challenges of building a startup from nothing, from 0 to 1 and beyond.

Enjoy my interview with Paolo. Feel free to check out Boxabl online. Think about how this can apply not only residentially but also commercially. If you’re ever in Vegas, book a tour of the Boxabl factory there in Vegas. They will take you around and show you everything that they’re doing. I’m sure you’ll find that very interesting. Share the interview with anyone that you think would benefit. Thank you for tuning in to Construction Genius.

—

Paolo, welcome to the show.

Thanks for having me. I love the show.

I’m excited to have you on because your perspective is one that has been kicked around in the construction industry for a long time. People understand that there’s this problem, but construction is essentially pre-industrial. You are working on rationalizing and industrializing the construction process. Tell us what you’re focused on and why it’s important for the industry.

Building construction is the largest consumer product that isn’t. What do I mean by that? I mean that everything that we buy and use in the modern world is made in a factory. Everything you’re looking at except buildings because buildings are big, and it’s been hard to put them in a factory until Boxabl. That means that they are pre-industrial. Pre-industrial simply means not being built in a factory. We get variable costs, long lead times, variable quality, and high costs typically. There are no economies of scale and no ability to use modern technology that the rest of our post-industrial world takes advantage of.

We can take advantage of those products and things that we’re used to when we buy a shirt on Amazon. We can do returns and we have high-quality standards like iPhone-level quality standards. We park all those notions when it comes to buildings. They’re not portable. You can’t do anything with them. It’s a big problem. The speed to scale is the epicenter of that problem. Boxabl frankly fixes all that.

When you begin to talk about offsite modular construction, I know much of my audience will be like, “I’ve been hearing this for the last 25 to 30 years. It’s like, ‘3D printing for construction,’ but that hasn’t happened yet.” There are three main issues that I see a lot with this idea of industrializing construction. One is that every single project in the mind of the people building it is unique. The second one is from a geographic location, there’s a whole bunch of different subs working on the project. The idea of the design that the owner wants is unique as well. All of these elements come into play. They present these massive roadblocks to the industrialization that you are describing. Tell me how Boxabl proposes to overcome these roadblocks.

Let me take this one step further back, if I may, to your question. Unfortunately, maybe throw a little bit of mark at the current factory-built industry. Coming from the top down, we have field construction. As you correctly pointed out, there are a lot of attempts at post-industrial production, i.e., putting buildings in a factory. Every single one to date takes 1 or 2 well-trodden and ineffective roads. The first is modular and trailer construction where they bring antiquated field tools like little nails, bits of wood, and nail guns, and put them in a factory. They use antiquated methods in a factory, which are not appropriate and not the best solution. They build something that’s 14-foot wide or 12-foot wide, and it’s illegally wide to ship, and then they ship it 200 miles. That’s not a solution.

The other solution is tiny homes. I feel for them. Those customers are looking for some freedom in their lives. They don’t like the high costs, but the tiny homes look nice in pictures. If I spread my arms, that’s 6-foot wide, and a tiny home is about 7-foot wide because you can only go 8.5-foot wide to go down the highway. If you put it on a regular flatbed, those ceiling heights are going to be in the 7 to 8-foot range. You’re living basically in a large coffin. It’s horrible. That’s the post-industrial marketplace now. It doesn’t work.

The question that’s great that you asked, which is one of the centers of what we do is that the customer is who we serve. The customer wants what they want. They want a layout, a style, and a price that dials in to their local economy. They want customization. We completely respect that. That’s one master that we must serve, and happily so. The other master we must serve to help fulfill that is that factories want to make repeatability. A factory wants to make a nut and a bolt of the same size. They want to bang them out, massive volume, great leverage with suppliers, repeatability, and the fewest number of unique components. We want massive rationalization in the factory.

How do we combine those two? How do we fix the first problem of making these very large buildings in a factory and then shipping them down the road legally? Our solution takes a couple of different approaches. First of all, one of the a-ha moments that we had at Boxabl was that about 2/3 of the volume in residential construction certainly is empty space. The remaining third, we call the dollar dense. Dollar dense means it’s dense in labor and expensive materials, everything from stairs to kitchens, partition walls, boiler rooms, and appliances.

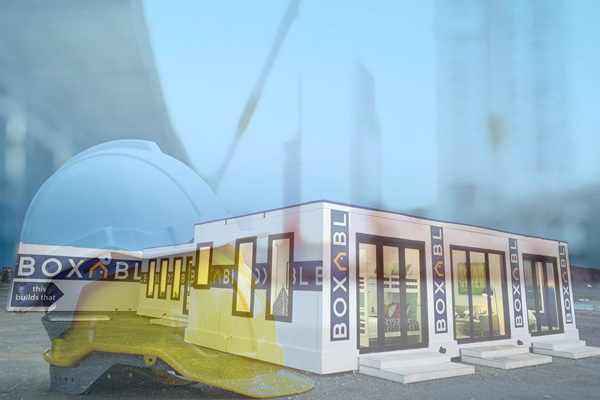

We realized, “Why don’t we just fold down the empty space and create a system that works with that?” We did the matrix-like. We fold down the empty space. It’s much easier said than done. It’s tons of engineering. That resulted in an 8.5-foot-wide product that unpacks to 20-foot wide on the short side, and 40-foot wide on the long side, providing a 9.5-foot ceiling height. We’ve even developed our own delivery system, which pays a lot of dividends. In terms of our two masters, the factory and the customer, our approach is not to build a finished home in a finished layout in a finished architectural style.

All around the world, we’re living on six sides. You walk to your bathroom, walk to your kitchen, walk to your living room, and look at the surfaces, you’ve got six sides to that surface, four ceilings and four walls or thereabouts. We said, “That’s interesting. Why don’t we make rooms that are architecturally neutral on the exterior? Let’s fit out the dollar-dense stuff on the interior. Let’s keep that neutral, clean and modern, and let’s see where we go.” If you think of Boxabl as little Legos you played with as a kid, the one with the four bumps, the little square one, and the one that’s double that size, the rectangular one with the eight bumps, and then the in-between one with the six bumps, the one that nobody uses, those are the three sizes.

If you think of how you can connect and stack and cantilever on those grid lines or bumps, you’ve pretty much got Boxabl, except that we then pack it down obviously to something narrow that can ship globally. We have these building shells. The building shells are the technology in three sizes. What can’t you build with a 20×40? That’s a 40-foot clear span with a 9.5-foot ceiling, 20-foot on the narrow side, and windows and doors that you can cut out, huge windows and doors with no header because our panel construction is post-industrial, all materials everywhere and massively strong. Everything inside is pre-chased. You have a professional audience. The chases are tunnels that run through the interior of our panels, floors and ceiling.

Every panel has a chase, horizontal and vertical chases. You can put smoke detectors or PEX lines wherever you want. It’s a building system that builds most of the things most of the time. Now you can start to see our two masters. Our factory is making those three boxes in different configurations, and we go into an ever-decreasing funnel of rationalization down to the washer. We’re extreme about this. What the factory sees is massive repeatability of scale. Those are our ambitions. We’re getting there quickly. What does the customer see? The customer sees ultimate customization with all the heavy lifting done for them.

The customer doesn’t care. The customer doesn’t say, “Can I bring that wall to 6 inches?” They say, “No, I need a Mediterranean three-bedroom with the master bedroom South facing over here, and I need the doorway over here. It’s got to be beautiful. I want it quickly. I want it at a low cost and high quality. I want you guys to take the liability of quality and any warranty issues that might come.” Those are the major pain points for developers. We’re like, “Yeah, we can do that.” That’s how we thread the needle where the factory makes repeatability, but the customer gets all the customization they want.

I get your concept there about the architecturally neutral, and what you bring to the site in terms of a home or whatever building you’re working on. In addition to that, what does your end user, the client or the customer need to bring to the table in order to complete the project?

What we will bring is everything complete from the outside of the walls in. That’s what we’re providing. We provide a lot of other useful elements to help the developer complete their project. I’ll run through it, all in terms of lowering costs. First of all, Boxabl ships on our own trailer systems. On our trailer system, we can pull two 40-foot Boxabls. Imagine that. Not with a big rig, but with a pickup truck. Imagine the cost savings there. It’s staggering and it gets better. Those Boxabls triple in size when they unpack. We’re delivering about 1,600 square feet or 800 square feet each on one pickup truck instead of six big rigs. That’s number one.

Number two, for any of your audience that works in the modular world or tried the modular product, for example, there are no overnight stops. We don’t have to park in a high school or a church parking lot overnight or anything like that. The developer or the onesie customer does not have to be home when we show up. All they have to do is say, “Put it over there.” We don’t care if the ground is level. We don’t need you to bring a crane. We will drop them off. Our driver will drop it off in about twenty minutes, and the ground does not have to be level. He or she can do it by themselves. That’s very important.

Number three, in terms of picking up the Boxabls and putting them together, no crane is needed. If you’re a developer and you have a crane on site, that’s all well and good, but the crane is expensive and it’s busy. That’s why you have it on-site. For us, we need a telehandler. A telehandler is a big forklift. You can pick it up and do up to two stories with the forklift, then you unpack the Boxabls. It’s matrix-style so it unfolds. Now we’re using a crane for that.

No crane is needed for picking up the Boxabl and putting them together. Click To TweetThe lowest common denominator for the unpacking would be like a crazy wild man at the top of a mountain where he can’t get his car and wants to make a cabin in the woods. Bear with me. We go to the lowest common denominator a lot. He says, “We can’t get a car there.” We’re like, “Two bodies, a mechanism, and an auto battery that a guy can get from Costco.” We’re developing that unpack mechanism. Obviously, two guys and a car battery. I know it sounds a little bit like Rube Goldberg, but it’s a lot less expensive than a crane. Now, we can do it with a telehandler.

In terms of the site work, we provide plans. We’re getting them to 50 states approved. You have to go to your local town for the basement. Boxabl is obviously shipped. They’re very strong. They don’t need a basement. Field-built construction requires a basement and a foundation, and they put all the little sticks on top. The foundation makes all the little sticks strong until it’s all sheathed up and everything. It’s still pretty weak. Boxabl obviously can travel thousands of miles. They can be held up with six concrete posts. We provide everything from a full basement to slabs to piers. We provide those plans, print them off, and take them to your local town. The site field workers put that together.

In terms of hook hookups, whatever the use case is, whether it’s a town, sewer or a well, regular water, gray water, electric or gas, Boxabl is all port to one corner and nothing goes underneath the product. It all ports out to the side. Going underneath things is a bad idea. We do it on our roads and we’re constantly digging them up. We don’t want to be digging up our houses when things break. Everything ports to one side. We made that easy. That’s the general arc. By the way, that delivery system can backhaul commodities like containers but specifically can also backhaul automobiles to further subsidize the cost of the delivery of the product. They’re efficient to ship.

Let me ask you specifically about the design element. You talk about the outside of the walls. What then does the client need to do in terms of customizing the appearance of the product, the house or whatever it is that you’re bringing on-site?

Your audience might know, customer number one was Elon Musk. He bought one of our prototypes pretty well. Customer number two was the Department of Defense, 156 units. For Guantanamo, they wanted steel exteriors for those units. Customer number three now is D.R. Horton. Your audience can be familiar with that, the largest home builder in the country. They’ve invested, by the way. They’ve ordered a few hundred units, I’m not sure exactly. Now we’re going to our consumer-grade, which is iPhone-quality grade building construction. We still have to learn how to make these things. In terms of materials, those are steel, concrete, and insulation.

The exterior is a hardy board. The latest Boxabls are clean with a modernist aesthetic on the exterior. You can certainly unpack these and go live in them, no problem. They are rectilinear with big windows. Any exterior finish, we call it dress-ups. It’s just gingerbread. It’s not required for any functional element, whether it’s rain drainage, ingress, wind loads or anything like that. You don’t need any of that. The developer can do facades or do the whole thing.

We’re experimenting now. We’ve got enough bandwidth. Even though we’re scaling rapidly without an engineering team, we have enough bandwidth now to get to the exterior portion. We’ll be developing exterior facades for developers. Those will be downloadable with cut sheets and everything. To give you an idea of the different types of exterior finish, we’ve got everything from adobes, contemporaries, and New England with shingles and siding. We’ve got a log version. We’ve even got some whimsical ones. One is a castle for the Casita models. It’s a 400-square-foot castle. Those are some of the things that we’re providing.

Tell me more about how you envisage Boxabl being applicable in the commercial space. I get the logic on the residential. Obviously, with D.R. Horton investing, they see some potential there that they want to explore. What about in the commercial arena?

As we scale, our focus is very much on residential because that’s where the biggest problem is. We’re not a charity. We are for profit, but I did start the company with my business partner to do good work. We are business minded. Scaling the residential side of things is number one. Our entry-level product is the Boxabl Casita which people sometimes incorrectly mislabel us as a tiny homemaker. The Casita is a configuration of the smallest building shell. It’s an ADU, Accessory Dwelling Unit as they call it in California. We have been stunned by the use case for people, and what they want to use them for. It’s shocking for us.

When I think about that and then I think about the commercial space, that we get into the commercial space. I’m sure people will find commercial applications for Boxabl in the commercial environment. I would say one of the metrics where we don’t fit is in huge clear spans. If you want a giant building, if you want to build a factory, you’re not going to build it with Boxabls. They would be too small. You’re not going to do that or auditoriums or anything like that. In the residential space, we’re looking to build most things most of the time. I know that we’re going to have a lot of fun building diners and things like that. Outlet malls would be a good use for that. We’ll be able to go up to five stories in production.

It doesn’t all have to come out of whole cloth either. For those commercial applications where you might have offices, meeting rooms and bathrooms, Boxabl can play a major role. It can be combined with traditional field construction when you’re doing tilt-up concrete. We’re not replacing tilt-up concrete warehouses, auditoriums, giant steel beams, stadiums, and things of that nature, but they all still need infrastructure. They still need some of the things I mentioned, lunch rooms, meeting rooms, bathrooms, and things like that. We don’t focus too much on that.

We have an order book that is mind-boggling, frankly. We all wake up every morning and say, “What the hell is going on?” We have an order book just for the Casita, which is the 400-square-foot studio home, for 150,000, which is staggering. I call it expressions of interest because they’re not all with deposits, but some of those expressions of interest are 110,00, 120,000 and 150,000. There is obviously a ceiling to sales, but it’s not visible from where we’re sitting right now.

When are you going to be shipping the Casita?

The Casita is shipping now as we get our C legs underneath us. The factory has been open for eighteen months from zero. If I could share a bit of pain with you and your audience. We moved in here a few years ago. Prior to that, we were in a 10,000-square-foot R&D facility. We are now in a 300,000-square-foot facility, 6 or 7 acres. We had to scale from zero. It wasn’t a car maker opening up another plant and bringing staff and engineering. We had to hire. It was interesting.

What was your biggest challenge with scaling?

Then, we weren’t scaling. I would say that was from 0 to 1. That was going from not being in production to being in production. Fortunately, we were fulfilling the Department of Defense order. They were very useful. They brought in skilled people on a bimonthly basis to help us. We also drafted in Porsche. Porsche, the automobile maker, has 700 consulting engineers for folks like us, whether you want to make little fizzy pop bottles going down a high production line or making houses. The way we make houses is mostly analogous to an automotive production line. They were very helpful. We got 200 people just on the factory side right now. We need to quintuple that. There were zero managers. We got through it and we delivered it.

Tell me the one reason Boxabl will fail.

If we can’t scale, we’ve accomplished nothing. If we can’t scale, we’ll just be another little regional factory builder. I tell you what’s not going to be a problem. Money is not going to be a problem. That’s an interesting story in and of itself. We’ve raised $150 million through crowdfunding with the most successful crowdfund possibly outside of digital coins. If we’re not, someone will correct me. We’re raising now. We think we can raise $1 billion through crowdfunding, which is completely insane.

If we can't scale, we've accomplished nothing. If we can't scale, we'll just be another little regional factory builder. Click To TweetThere are other guys and gals who are doing this thing, or they’re trying it. They maybe not getting as much traction. Why are you guys getting that traction in terms of crowdfunding and also various people offering you and someone like D.R. Horton investing in you?

There are three parts to that. The onesie is every customer is a fan. They see freedom. When they see the Casita, they don’t see the building system. They just see the Casita. The Casita, with those 150,000 unique orders, which each may be multiples, will ultimately be less than 1% of our business. That’s the insane scale we’re talking about. The fans, a lot of them are educated. They’re just fans. It’s freedom. The D.R. Hortons of the world see that they have a massive problem. They see that we’re the only people that address the entirety of the problem with functional solutions. Other people are making, “Do you want to buy this style of home? Do you want to buy that A-frame home? Do you want to buy that tiny home?”

That’s not going to play on a global level. You have to cater to people’s regional styles. D.R. and all, we’re talking to them all. The folks at D.R. have been fantastic for us. They see the problem. They can identify all the pain points. They see that we theoretically fix every single last one of those pain points because we’re doing it now. They are all rushing in. It’s humbling. D.R. is a storied company since the ’60s. These are professional friends. To have their interest and help is great.

How are you going to address the challenge? You’re bringing the product to the customer. I’m assuming, at that point, you provide installation. You’re going to have to then interact with other contractors. It sounds to me like that’s going to be a lot of hassle. At the end of the day, the customer wants their Casita or they want their home or whatever it is that you’re providing, and yet there’s still that contractor-producer dynamic that can cause a lot of friction and cost. How do you propose to handle that aspect of it?

Our providing solutions don’t end at our factory doors and we wave goodbye to the Casita. There are two types of customers. There’s the onesie customer and there’s the developer customer. We’re focused on the developer customer right now, friends and family type. We don’t know them and they’re not family, but they’re professional people. Whereas the onesie customer is the retail customer that has a crazy standard of what they expect in a post-industrial world. We’re not quite there yet. They have the right to demand that.

How do we fix that? How do we make the glue from our product to being set and somebody living in it? We’re now planning Boxabl University. It’s a pretty hardcore course. You’ve got to come for a couple of weeks. There will be different grades of the installer and you’ll be a certified installer. Those certified installers are certainly going to be our developers. They’re going to be a lot of the regional guys and real-world examples from D.R. Horton. We’ll have classrooms and we’ll make it fun. There will also be an online digital course, the Big Planet, Big Country. That’s how we’ll get the information across to provide glue. The developer will have their own crews.

Are you looking then to cut out the contractor at the local level? I don’t mean that in a negative way, but to put your own people on the ground at a local level to mitigate that challenge of multiple contractors working on a project?

Not our people. We wouldn’t be cutting out those contractors. Not only would we be training them as the network grows, but we’d also be feeding them customers and sales.

Let me rephrase it in a different way. Would it be like the auto manufacturer and the car dealers?

Yes and no. When the car arrives, it’s pretty much done. They might throw bigger wheels on it or something. It’s probably not the most accurate analogy. I would call them certified installers. I suppose a new business model. That’s fairly straightforward. We’re doing that now with developers. The reality of developers who are professional people and can provide intelligent feedback and assistance is what we’re doing there. We’re excited about Boxabl University. Kid At Heart University sounds great.

The reality is that professional developers can provide brilliant feedback and assistance. Click To TweetOn the onesie customer, we have a great plan. That plan is going to be the Big Box Outlets. A customer can come directly to us, but they will find some preconfigured solutions let’s say in a parking lot outside Home Depot. The lovely thing about Home Depot and the other Big Box Outlets and Lowe’s in this country is they have two types of customers. They have the regular Joe, and then they have the pro customer. They have a database of their pro customers. Those pro customers can become certified installers. It works for everybody.

Let’s take the onesie customer that goes to Home Depot as an imaginary example. They see that there’s a Boxabl in the parking lot, and they tour it. They go, “This is so great. I don’t know. I’m an accountant. I have no idea.” The Big Box reseller can hook them up with a certified installer who’s already their customer and let them work it out. Who gets what out of this? We deliver products efficiently. The Big Box Outlet has no cost of goods, no returns, and no inventory apart from the model. Profits fall straight to the bottom line. That’s pretty staggering for them.

The onesie customer has a connection to the factory with the certified installer and has recourse, “I don’t like him. He didn’t do this. He didn’t do that.” He’s going to do this and that if he wants more business from us. It’s a three-way relationship that is healthy for that onesie customer. For that certified installer, for the Lowe’s or the Home Depot pro, it’s fantastic because they’re not just an installer. That onesie customer needs a foundation, needs someone to go to the town hall, needs to put a driveway in or might need a nice garage.

We are reorganizing the industry to make sense. We don’t see anybody losing in the equation. Everybody does more faster for less. There are plenty of runways because the problem is big. We’re going to enable everybody. We’re not there yet with the Big Box. We haven’t reached out to them. I had a previous career. I sold billions of dollars of products. I put a lot of meals on the table for the Big Box Outlet. I know them rather well, but we haven’t reached out to them, and we will.

That’s the onesie plan and the developer plan. We’re doing it in an ad hoc way now. We’re doing a community of 180 homes to 200 homes for a mining community in Bagdad, Arizona. Great guys. We have an eightplex. They’re all apartments. They are coming down to get trained. Their installers are coming down to get trained. During these early days, we have our own install teams. We deliver products, and the team scatters and helps their installers. We’re learning along with them. As with all things Boxabl, it gets systemized and documented. Ultimately, it can be repeatable and franchisable.

The way that you’re looking at it at the moment, it sounds like you’ve got this big residential market. That’s what you’re going to go after in terms of solving that problem. The commercial market would be something that you would look at down the road. Did I get that right?

Yes. The commercial market has to look at us the other way around and see if we are a fit for them. What we plan to make forever in a day is three sizes of building shells which we spent God knows how many hours. We’re a funny company. We have in the office a lot of engineers here. We have precisely nobody but the building construction. We have chemical engineers and aerospace engineers. Our third founder came from the building construction industry. That’s it. It’s a different mix of people that we have here.

How can people get in touch with you, Paolo? How can they learn more about the company?

It’s Boxabl. We are in glorious Las Vegas, Nevada, which turned it to be a spectacularly amazing location to put down roots for a company like this. If you live in Kentucky or Boise to come and visit the factory, maybe people don’t want to come, with all respect to those lovely places. When you say you’re in Las Vegas, people find a reason to come see you. We’re fifteen minutes short ride north. We give what we call Disney Tours at the factory here.

It’s a different way of thinking about a business. It’s huge crowdfunding. We’re very appreciative of our fans. We set up a Disney tour. When I say a Disney tour, we have gates that open. The fans and customers that come put on PPE, which is a form of costume. We have a store. We have roadways and we have a little 3-foot cartoon pig. It’s a destination, but there’s a lot of serious business behind that. It’s a great place to visit.

That’s awesome. Paolo, I appreciate you joining us and walking us through the process. I got to ask you one more question. I’m visiting Vegas, and I know this may be a difficult question to answer, but what’s the one restaurant I need to hit when I visit Vegas?

That’s not difficult for me. Panevino. It’s Italian. It means bread and wine. Please ask for Vincenzo, who’s a colorful gentleman and maître d. Please give him my name. He will hug you and kiss you. Don’t give my name if you don’t want that. The food is delicious. Please do get in touch or share my cell when we’re finished. Please do come by. It’s great to meet you personally. It would be wonderful.

That would be great. If you’re in Vegas, you can take that tour of the factory. I know there are lots of folks who go to Vegas for conventions and things like that, so they can put that on their itinerary and check out what you guys are doing there with Boxabl. I appreciate your time here, Paolo. I look forward to talking to you again about how the journey that you guys are on and the successes that you have had. Thanks for joining us here.

Thank you so much. I enjoyed very much chatting with you.

—

If you’re ever in Vegas, book a tour to check out Paolo’s factory there at Boxabl, and go to their website, Boxabl.com. Before you bounce for the day, I would like to encourage you to go to Amazon right now and purchase yourself a copy of my book, Construction Genius: Effective, Hands-On, Practical, Simple, No BS Leadership, Strategy, Sales, and Marketing Advice for Construction Companies. If you’re a construction company owner or leader, it is the one book that you must read. I was talking to my daughter and she asked me, “How much are you selling your book for?” I said, “$19.99.” She said, “That’s a lot of money. Is it worth it?” I told her, “Yes, because if you use and apply the insights that you learn from the book, it can make you millions.” Go and buy it. I know you’ll get tremendous value from it. Thank you for tuning in to Construction Genius.

Important Links

- Boxabl

- Construction Genius: Effective, Hands-On, Practical, Simple, No BS Leadership, Strategy, Sales, and Marketing Advice for Construction Companies

- https://www.Facebook.com/boxabl/

- https://www.Instagram.com/boxabl/

- https://www.LinkedIn.com/in/paolo-tiramani/

About Paolo Tiramani

Mr. Tiramani’s work is manifold; he holds 155 patent filings, covering a diverse mix of inventions and intellectual property, including hardware, housewares, juvenile, sporting goods, medical, personal care, construction, and automotive.